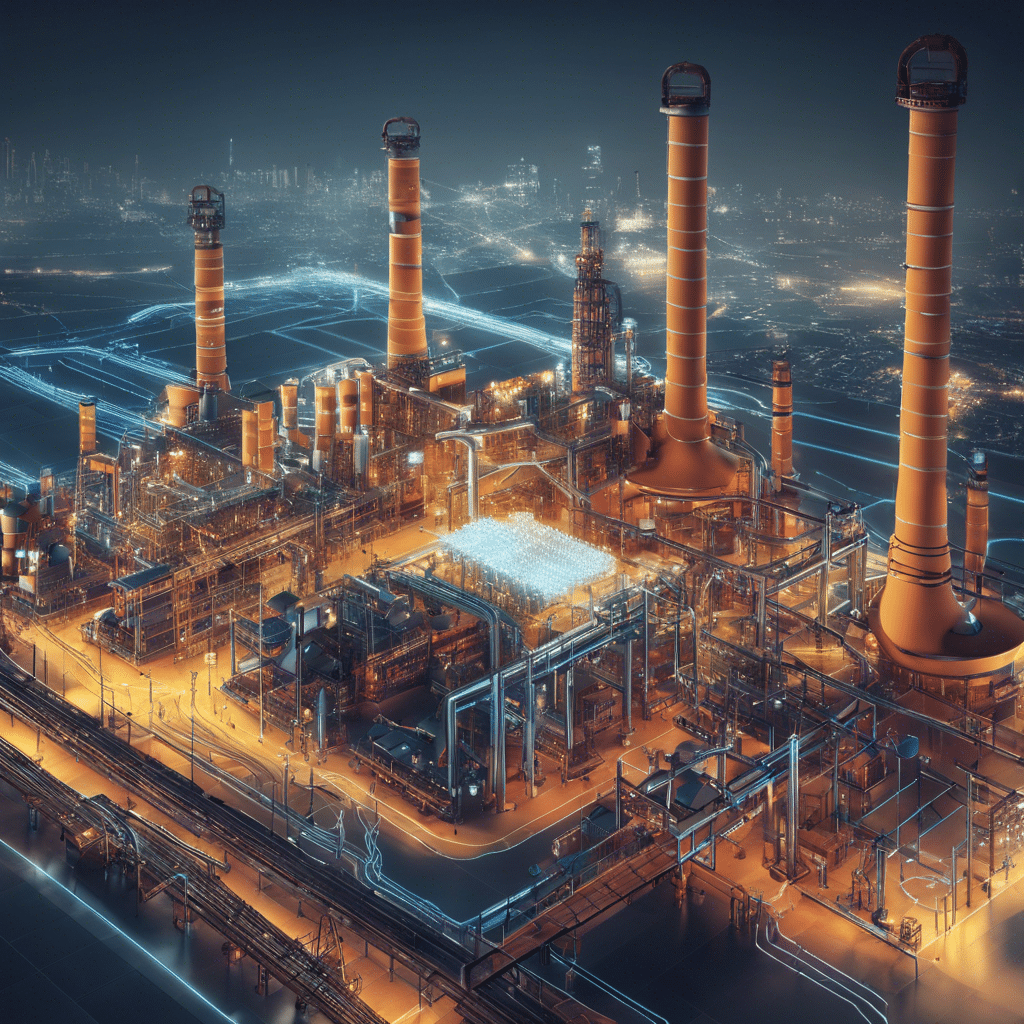

The Smart Factory Revolution

Manufacturing has experienced its most significant transformation since the assembly line. IoT sensors are turning traditional factories into intelligent, self-optimizing powerhouses of efficiency.

Manufacturers are racing to implement innovative technologies, with the industrial IoT market projected to reach $1.55 trillion by 2028. Early adopters are seeing 15-30% reductions in maintenance costs and 20-25% increases in production output.

The question isn’t whether to adopt IoT – it’s how quickly you can implement it before competitors gain an insurmountable advantage.

Real-Time Monitoring and Predictive Maintenance

Imagine knowing exactly when a machine will fail before it happens. That’s the reality of IoT-enabled predictive maintenance. Smart sensors continuously monitor equipment health, detecting subtle variations that signal potential issues.

Our manufacturing clients are slashing downtime by up to 45% through predictive maintenance. These systems analyze real-time vibration patterns, temperature fluctuations, and performance metrics, enabling maintenance exactly when needed – not too early or too late.

The impact on the bottom line is staggering. A single hour of downtime can cost manufacturers up to $50,000 per minute of downtime. IoT predictive maintenance systems are cutting these losses dramatically.

Smart Manufacturing Processes

IoT is transforming quality control from sample-based inspection to 100% automated verification. Smart cameras and sensors check every product, catching defects human inspectors might miss.

Connected inventory systems eliminate stockouts while reducing carrying costs by 20-30%. Real-time tracking enables just-in-time production, optimizing cash flow and warehouse space.

Energy consumption monitoring through IoT delivers 10-20% savings on utility costs. Smart systems automatically adjust power usage based on production demands, ensuring energy is used only when needed.

Data-Driven Decision Making

The real power of industrial IoT lies in the data. Manufacturing executives now have real-time visibility into every aspect of their operations, enabling truly informed decision-making.

Our systems process millions of data points per minute, converting raw information into actionable insights. Production managers can spot bottlenecks instantly, optimize workflows in real time, and make data-backed decisions that drive efficiency.

Advanced analytics platforms predict maintenance needs with 92% accuracy, forecast demand patterns, and optimize production schedules automatically.

Transform Your Manufacturing with Seisan

The potential of IoT in manufacturing is clear, but implementation requires expertise. Seisan brings deep experience in industrial IoT solutions, combining technical knowledge with practical manufacturing insights.

We focus on creating scalable IoT systems that align with your specific manufacturing needs and goals. We understand both the technical complexities of IoT implementation and the practical realities of manufacturing environments.

Don’t wait to explore how IoT can enhance your manufacturing operations. Contact Seisan today to discuss your specific challenges and goals.

Ready to learn more about smart manufacturing solutions? Our IoT experts can help you understand the opportunities for your facility.

The future of manufacturing is connected, intelligent, and efficient. Let’s work together to explore how IoT can benefit your operations.